What is the function of the ejector pin in the plastic mold?

The ejector pin is necessary for plastic injection molds, ejecting the injection-molded plastic parts!

In the process of injection molding, the molten resin is injected into the mold to make a plastic part, as the solidified plastic part will stick to the mold, so the ejector pin is used to eject it from the mold.

Ejector pins can cause defects in injection-molded plastic parts.

If misused, the ejector pin will damage the injection-molded plastic parts

When the ejector pin is ejected out of a plastic part, the part is still in a hot and soft state, so that the part may result in deformation, unevenness, burr, ejector pin marks, pin push, etc.

For such defects caused by the ejector pin, we should try and find the best way to minimize its adverse effects.

How to use the ejector pin properly?

- Multiple ejector pins arranged in an ejector system should make the resistance of each ejector pin as consistent as possible.

- The complex areas that need to overcome the demolding forces are larger than others, so the number of ejector pins should be increased accordingly.

- The ejector pin should be placed in a position that enables it to take effect, such as a pillar, reinforcing rib, step, metal insert, partially thick wall, and other complex structure areas.

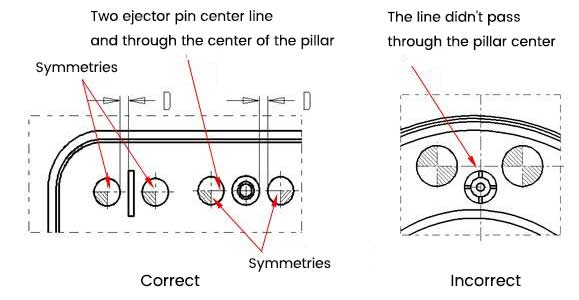

The ejector pin should be arranged as symmetrically as possible beside the pillar, and the spacing should be 1.5mm, as shown in Figure 1; in addition, should try to ensure that the two ejector pin center line and through the center of the pillar.

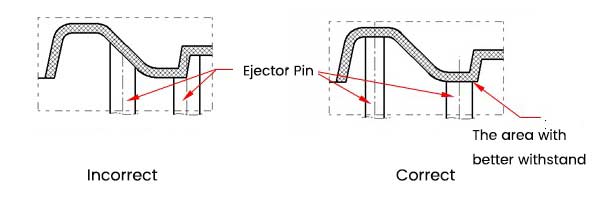

- The ejector pin should be placed in an area with better withstand; avoid setting it on the slope or step; the top surface of the ejector pin should fit parallel to the glue surface. As shown in Figure 2.

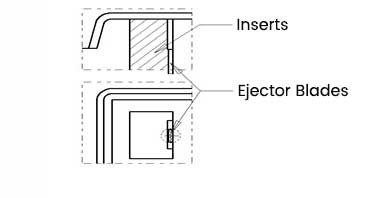

- Higher reinforcing rib (height ≥ 20mm), when it is difficult to place round ejector pins, should replace with ejector blades. When using ejector blades, better use inserts as far as possible. As Figure 3

- The ejector pin can not be placed on the appearance surface for parts requiring appearance and should use other ejection methods.

- The ejector pin layout should consider the distance from the cooling channel and avoid water leakage.

- Consider the exhaust function of the ejector pin; to exhaust when ejecting, the ejector pin should be placed in the areas where the vacuum is easily formed.

- For transparent plastic parts, the ejector pin should not be placed on the areas that need to transmit light.

What kind of ejector pin should be chosen?

- If possible, try to use the larger diameter one.

- The specifications of the ejector pin should be as few as possible.

- The ejector pin should be selected to meet the ejector force requirements. The ejector pin should withstand greater pressure to avoid small ejector pin bending deformation; when the diameter of the ejector pin is less than 2.5mm, that should be selected shoulder ejector pin.

- Plastic injection mold ejector pin material includes SKH51, SKD61, SKD11, 65Mn, etc.; SKH51 is tougher; SKD61 can resist 1600℃ high temperatures. SKD61 ejector surface nitriding treatment can be excellent for improving the wear resistance of the ejector.

Alternatives of ejector pin

In the ejector system of plastic injection mold, besides the ejector pin, there are various ejector methods, including ejector sleeves, ejector blades, core pins, knockout rod extensions, air ejector pins, ejector plates, etc.; they have different characteristics and application scenarios.

A mold designer must consider which ejector method should be used when taking over a project to meet the project’s needs. So let’s kick off with finding the best ejector solution.